Are you ready to unleash your creativity and take your crafting game to the next level? Look no further than laser cutters! These cutting-edge machines have revolutionized material processing, allowing artists, designers, and DIY enthusiasts to bring their wildest imaginations to life.

From intricate patterns on wood and acrylics to precise cuts in fabric and metal, laser cutters are the ultimate tool for crafting innovation.

Join us as we dive into the world of laser cutters in this blog post, exploring their endless possibilities and uncovering how they have become a game-changer in modern artistry. Get ready to be inspired!

An overview of the history and development of laser cutting technology

Laser-cutting technology has revolutionized the world of material processing, offering precision, flexibility, and efficiency in cutting various materials. But where did this technology come from? How has it evolved over the years? In this section, we will provide an in-depth overview of the history and development of laser-cutting technology.

The concept of using a focused beam of light to cut through materials was first introduced in the 1960s by physicist Theodore Maiman. He developed the first working laser using a ruby crystal as its medium. However, it wasn’t until the 1970s when researchers at Bell Labs discovered that they could use carbon dioxide (CO2) lasers to cut metals with high precision.

In the early days, laser cutting was primarily used for industrial purposes, such as drilling holes in diamonds and creating intricate patterns on metal surfaces. It wasn’t until the late 1980s, when advancements in computer technology allowed for more precise control over the laser beams, that laser cutting became a popular method for material processing.

Advantages of using laser cutters compared to traditional cutting methods

Laser cutting is a modern technology rapidly gaining popularity in various industries, such as manufacturing, fashion, and crafting. It involves using a high-powered laser beam to cut through materials precisely and accurately.

This innovative method offers numerous advantages over traditional cutting methods, making it the preferred choice for many professionals and hobbyists.

In this section, we will discuss some of the key advantages of using laser cutters compared to traditional cutting methods:

- Precision and Accuracy:

One of the most significant advantages of laser cutters is their ability to produce precise cuts with unparalleled accuracy. The high-powered laser beam allows intricate designs and shapes to be cut with incredible precision, even on delicate materials. This level of precision cannot be achieved with traditional cutting tools such as scissors or knives. - Versatility:

Laser-cutting machines are incredibly versatile and can be used on various materials such as wood, metal, plastic, fabric, paper, and more. This versatility makes them an ideal tool for various industries where different materials must be processed.

Tips for choosing the right laser cutter for your needs

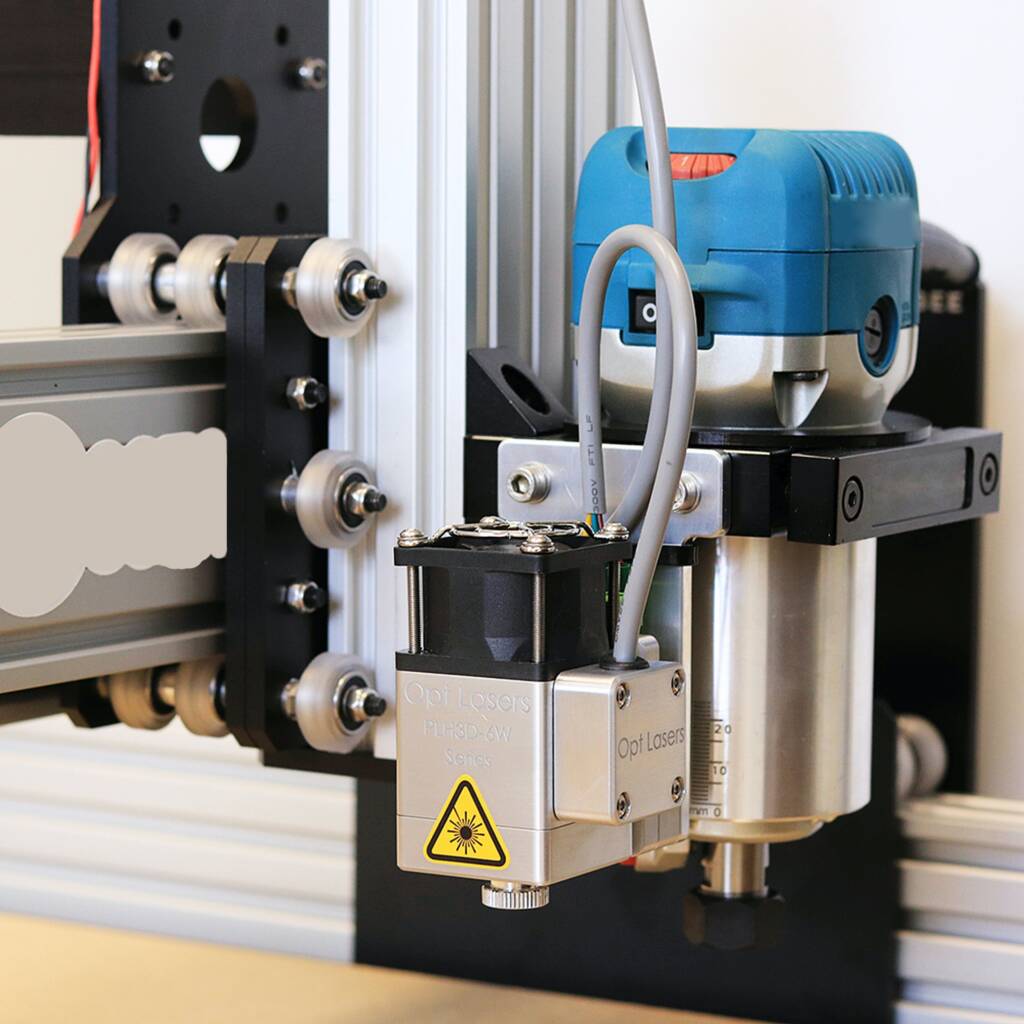

Laser cutters are powerful tools that enhance your crafting or manufacturing capabilities significantly. These machines use a high-powered laser beam to cut through various materials with precision and speed, making them ideal for creating intricate and detailed designs.

However, with so many different types of laser cutters available in the market, choosing the right one for your specific needs can be overwhelming. This section will discuss some essential tips to help you select the perfect laser cutter for your projects.

- Consider Your Material Requirements:

The first step in choosing the right laser cutter is to determine the type of materials you will be working with regularly. Laser cutters come in different power levels and are designed to work on specific materials such as wood, acrylic, leather, fabric, metal, etc. Some machines may also have limitations on the material thickness they can cut through. Therefore, understanding your material requirements is crucial in determining which laser cutter model will best suit your needs. - Evaluate Cutting Speed and Precision:

A laser cutter’s cutting speed and precision are essential factors that can significantly affect your project’s outcome. If you need to produce projects quickly or require highly precise cuts, opt for a machine with faster cutting speeds and better accuracy. Additionally, consider whether you need a machine with engraving and cutting capabilities, as some models may specialize in one function.

Safety precautions when working with laser cutters

When working with laser cutters, it is important to take certain safety precautions to ensure the well-being of yourself and those around you. Laser cutters use a high-powered laser beam to cut through various materials precisely, making them powerful tools for crafting and material processing.

However, this also means they can be potentially hazardous if not used properly.

Here are some safety precautions to keep in mind when working with laser cutters:

- Wear Appropriate Protective Gear:

It is crucial to wear protective gear when operating a laser cutter. This includes safety glasses or goggles specifically designed for use with lasers, as well as gloves and closed-toe shoes. These items will help protect your eyes and skin from potential hazards, such as flying debris or accidental exposure to the laser beam. - Familiarize Yourself with the Machine:

Before using a laser cutter, ensure you are familiar with its operation by carefully reading the manufacturer’s instructions. Each machine may have different features and settings, so it is important to know how yours works before using it.

Future advancements and possibilities in the field

Technological advancements have greatly impacted the material processing field, and laser cutters are no exception. As we continue to push the boundaries of what is possible, some exciting developments on the horizon will further enhance the capabilities and possibilities of laser cutters.

One area where we can expect to see significant advancements in the future is in the size and scale of laser-cutting machines. Currently, most laser cutters have a limited cutting bed size, which restricts the size of materials that can be processed.

However, with ongoing research and development, larger and more powerful laser cutters that can handle larger sheets or even entire rolls of material are being developed. This will open up new avenues for industrial applications, such as cutting large pieces for construction or automotive industries.

In addition to size, speed is another key factor in advancing laser cutter technology. The current generation of laser cutters already operates at impressive speeds, but there is still room for improvement.

Production times can be reduced significantly with faster processing speeds while maintaining high precision and accuracy levels. This would increase efficiency and allow for quicker turnaround times for clients.